-

News

News TianChang News

TianChang News-

TianChang News

TianChang News -

TianChang Information

TianChang Information -

TianChang Product

TianChang Product

-

-

Products

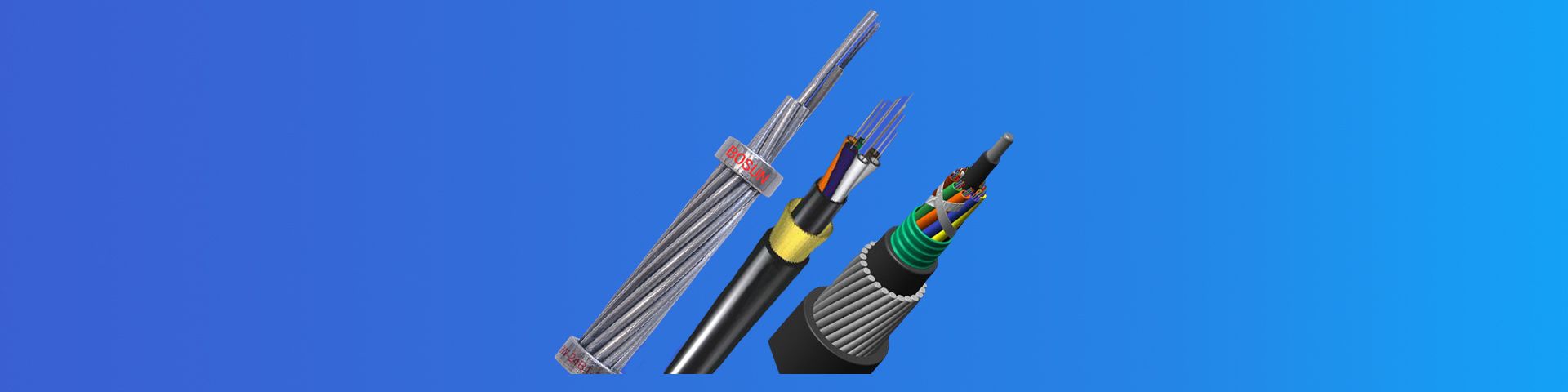

Products Used for outdoor optical cable, belongs to a kind of optical cable, because the most suitable for outdoor so called outdoor optical cable, it is durable, can withstand the wind and the sun, the outer packing is thick, with pressure resistance, corrosion resistance, tensile resistance and some mechanical characteristics, environmental characteristics.

Used for outdoor optical cable, belongs to a kind of optical cable, because the most suitable for outdoor so called outdoor optical cable, it is durable, can withstand the wind and the sun, the outer packing is thick, with pressure resistance, corrosion resistance, tensile resistance and some mechanical characteristics, environmental characteristics.-

Used for outdoor optical cable, belongs to a kind of optical cable, because the most suitable for outdoor so called outdoor optical cable, it is durable, can withstand the wind and the sun, the outer packing is thick, with pressure resistance, corrosion resistance, tensile resistance and some mechanical characteristics, environmental characteristics.

Used for outdoor optical cable, belongs to a kind of optical cable, because the most suitable for outdoor so called outdoor optical cable, it is durable, can withstand the wind and the sun, the outer packing is thick, with pressure resistance, corrosion resistance, tensile resistance and some mechanical characteristics, environmental characteristics. -

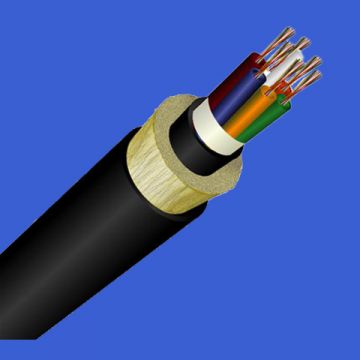

Indoor optical cable is the optical cable laid in the building, mainly used for communication equipment, computers, switches and end-user equipment in the building.To get the message across.

Indoor optical cable is the optical cable laid in the building, mainly used for communication equipment, computers, switches and end-user equipment in the building.To get the message across. -

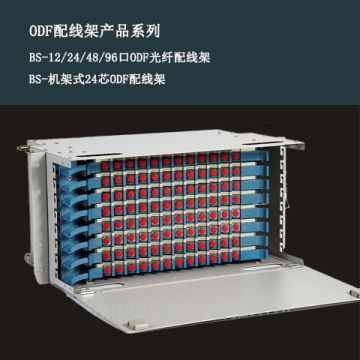

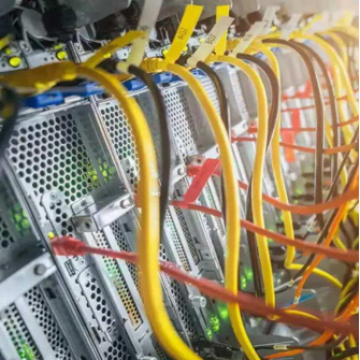

Fiber optic distribution frame is an important supporting equipment in optical transmission system. It is used for optical fiber fusion of optical cable terminal, adjustment of optical connector, storage of excess tail fiber and protection of optical cable and other functions.

Fiber optic distribution frame is an important supporting equipment in optical transmission system. It is used for optical fiber fusion of optical cable terminal, adjustment of optical connector, storage of excess tail fiber and protection of optical cable and other functions. -

Cable connection box, also called cable connector box and the gun barrel, is the place where the end of the cable connection, and then through the optical fiber jumper wire connected to the light switch, prevent heat, cold in nature, light, material aging caused by oxygen and microorganism.

Cable connection box, also called cable connector box and the gun barrel, is the place where the end of the cable connection, and then through the optical fiber jumper wire connected to the light switch, prevent heat, cold in nature, light, material aging caused by oxygen and microorganism. -

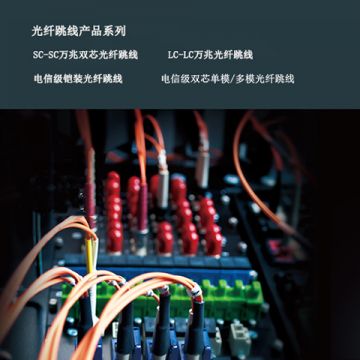

Fiber optic jumpers are used for jumpers from equipment to fiber optic cabling links.It has a thick protective layer, which is generally used in the connection between optical terminal machine and terminal box. It is applied in some fields such as optical fiber communication system, optical fiber access network, optical fiber data transmission and local area network.

Fiber optic jumpers are used for jumpers from equipment to fiber optic cabling links.It has a thick protective layer, which is generally used in the connection between optical terminal machine and terminal box. It is applied in some fields such as optical fiber communication system, optical fiber access network, optical fiber data transmission and local area network. -

Special optical cable

Special optical cable -

Optical cable intelligent monitoring system

Optical cable intelligent monitoring system

-

-

Solutions

Solutions Operator Case

Operator Case-

Operator Case

Operator Case -

Government and military characteristic cases

Government and military characteristic cases -

Airport and rail transit cases

Airport and rail transit cases -

High speed case

High speed case -

Smart City Cases

Smart City Cases -

Real estate, hotel cases

Real estate, hotel cases

-

-

Services

Services Tiangyong communication technical solutions mainly include the solution for customers to pre-sale services and product maintenance and other basic services, so that each consumer to buy quality products and services, but consumers are often easy to be confused by some false impression, and into the "quality products" misunderstandings

Tiangyong communication technical solutions mainly include the solution for customers to pre-sale services and product maintenance and other basic services, so that each consumer to buy quality products and services, but consumers are often easy to be confused by some false impression, and into the "quality products" misunderstandings-

Tiangyong communication technical solutions mainly include the solution for customers to pre-sale services and product maintenance and other basic services, so that each consumer to buy quality products and services, but consumers are often easy to be confused by some false impression, and into the "quality products" misunderstandings

Tiangyong communication technical solutions mainly include the solution for customers to pre-sale services and product maintenance and other basic services, so that each consumer to buy quality products and services, but consumers are often easy to be confused by some false impression, and into the "quality products" misunderstandings -

We take customer satisfaction as the tenet, timely response to customer needs as the key, to provide high value services for customers as the goal, with customized customer support service solutions, to win the market and customer respect.

We take customer satisfaction as the tenet, timely response to customer needs as the key, to provide high value services for customers as the goal, with customized customer support service solutions, to win the market and customer respect. -

Tianchang communication channel management mainly includes channel announcements, channel policies, etc., the search of partners

Tianchang communication channel management mainly includes channel announcements, channel policies, etc., the search of partners

-

-

Resources

Resources Guangzhou tianchang communication technology co., LTD is looking for a position

Guangzhou tianchang communication technology co., LTD is looking for a position-

Guangzhou tianchang communication technology co., LTD is looking for a position

Guangzhou tianchang communication technology co., LTD is looking for a position -

Employees Story

Employees Story -

Cultivation of Talents

Cultivation of Talents -

In order to make the human resource system run effectively, we undertake the company's strategy, culture and core competitiveness, constantly introduce the industry's advanced methodology and best practices, and learn from the industry and cross-border benchmarking and advanced enterprises, so as to continuously optimize the human resource system

In order to make the human resource system run effectively, we undertake the company's strategy, culture and core competitiveness, constantly introduce the industry's advanced methodology and best practices, and learn from the industry and cross-border benchmarking and advanced enterprises, so as to continuously optimize the human resource system

-

-

laboratory

laboratory Laboratory Profile

Laboratory Profile-

Laboratory Profile

Laboratory Profile -

The Scientific Research Direction

The Scientific Research Direction -

The latest News

The latest News -

Open Topic

Open Topic

-

-

About Us

About Us Contact Us

Contact Us-

Contact Us

Contact Us -

Telecommunications, Mobile, Unicom, Radio and Television, Power, Transportation, Military, Intelligent Building, Government, Public Security, Real Estate, Manufacturing, Education, Hospitals, Finance...

Telecommunications, Mobile, Unicom, Radio and Television, Power, Transportation, Military, Intelligent Building, Government, Public Security, Real Estate, Manufacturing, Education, Hospitals, Finance... -

Through the tyre certification and ISO9001 international quality system certification, and in accordance with the tyre certification and ISO9001 international quality system operation requirements, has established a set of efficient production process, perfect process guidance system and process quality continuous monitoring system.

Through the tyre certification and ISO9001 international quality system certification, and in accordance with the tyre certification and ISO9001 international quality system operation requirements, has established a set of efficient production process, perfect process guidance system and process quality continuous monitoring system. -

企业定位:通信产品整体解决方案服务商。业务涵盖光缆、光缆智能监测系统的生产、销售以及提供客户所需的通信整体解决方案。 企业愿景:打造通信行业(BOSUN)国际知名品牌,成为优秀的通信解决方案提供商。 企业使命:让通信更流畅, 让沟通无障碍。 价值理念:诚信、务实、 创新、尽责。

企业定位:通信产品整体解决方案服务商。业务涵盖光缆、光缆智能监测系统的生产、销售以及提供客户所需的通信整体解决方案。 企业愿景:打造通信行业(BOSUN)国际知名品牌,成为优秀的通信解决方案提供商。 企业使命:让通信更流畅, 让沟通无障碍。 价值理念:诚信、务实、 创新、尽责。 -

As a core technology brand in optical communication field, BOSUN has become an excellent representative among the national "innovative enterprises". Every year, 18% of the sales revenue will be invested in R&D, of which 38% will be invested in future high-end technology R&D.Over the years, BOSUN has made steady progress on the innovation road of independent research and development, leading and promoting the rapid development of cutting-edge optical communication technology.

As a core technology brand in optical communication field, BOSUN has become an excellent representative among the national "innovative enterprises". Every year, 18% of the sales revenue will be invested in R&D, of which 38% will be invested in future high-end technology R&D.Over the years, BOSUN has made steady progress on the innovation road of independent research and development, leading and promoting the rapid development of cutting-edge optical communication technology.

-

- Products

- Outdoor fiber optic cable

- The indoor optical fiber cable

- Fiber optic distribution frame

- The characters box

- Fiber optic jumper

- Special optical cable

- Optical cable intelligent monitoring system

Welcome To Guangzhou TianChang Communication Technology co., LTD!

Language